What is a Ball Valve?

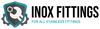

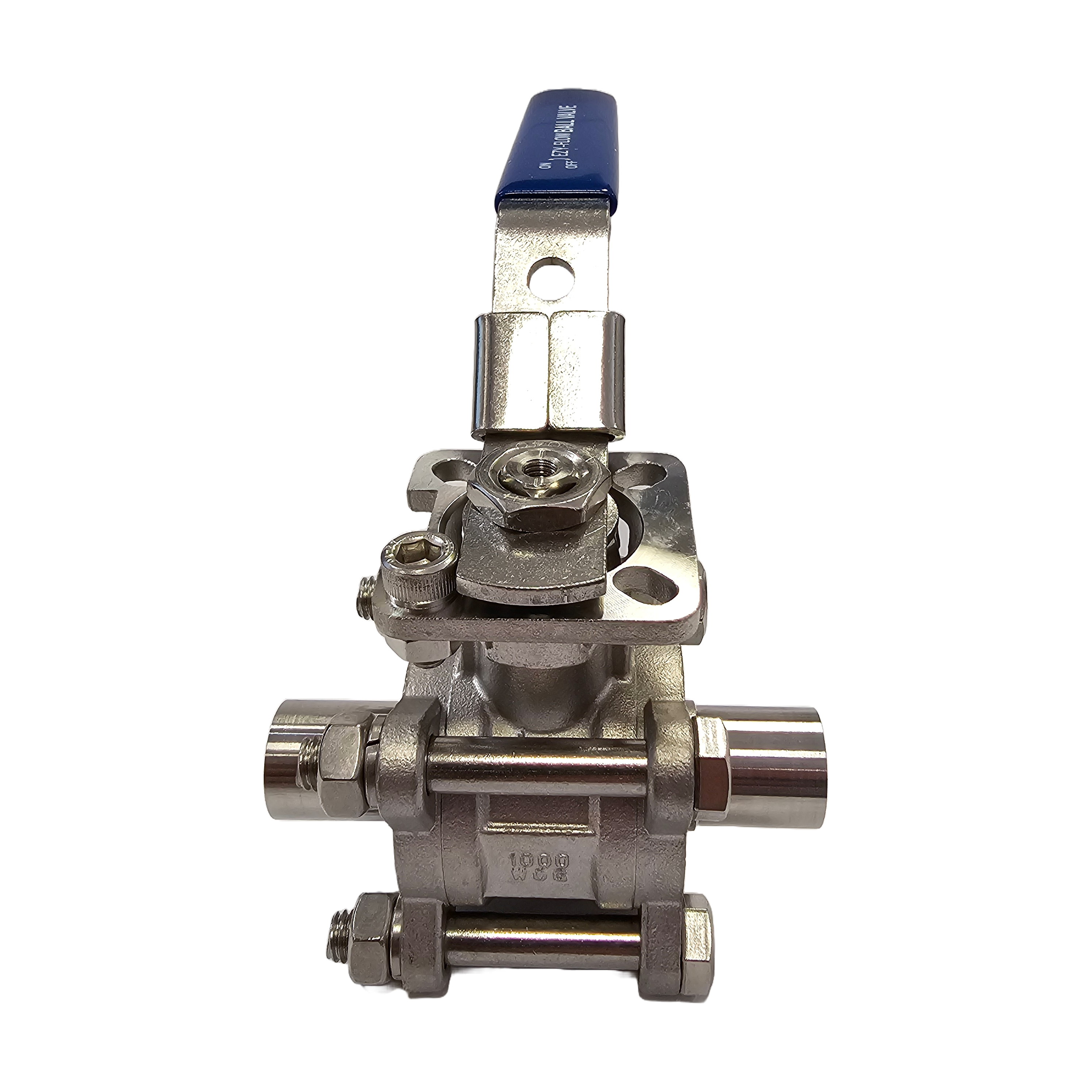

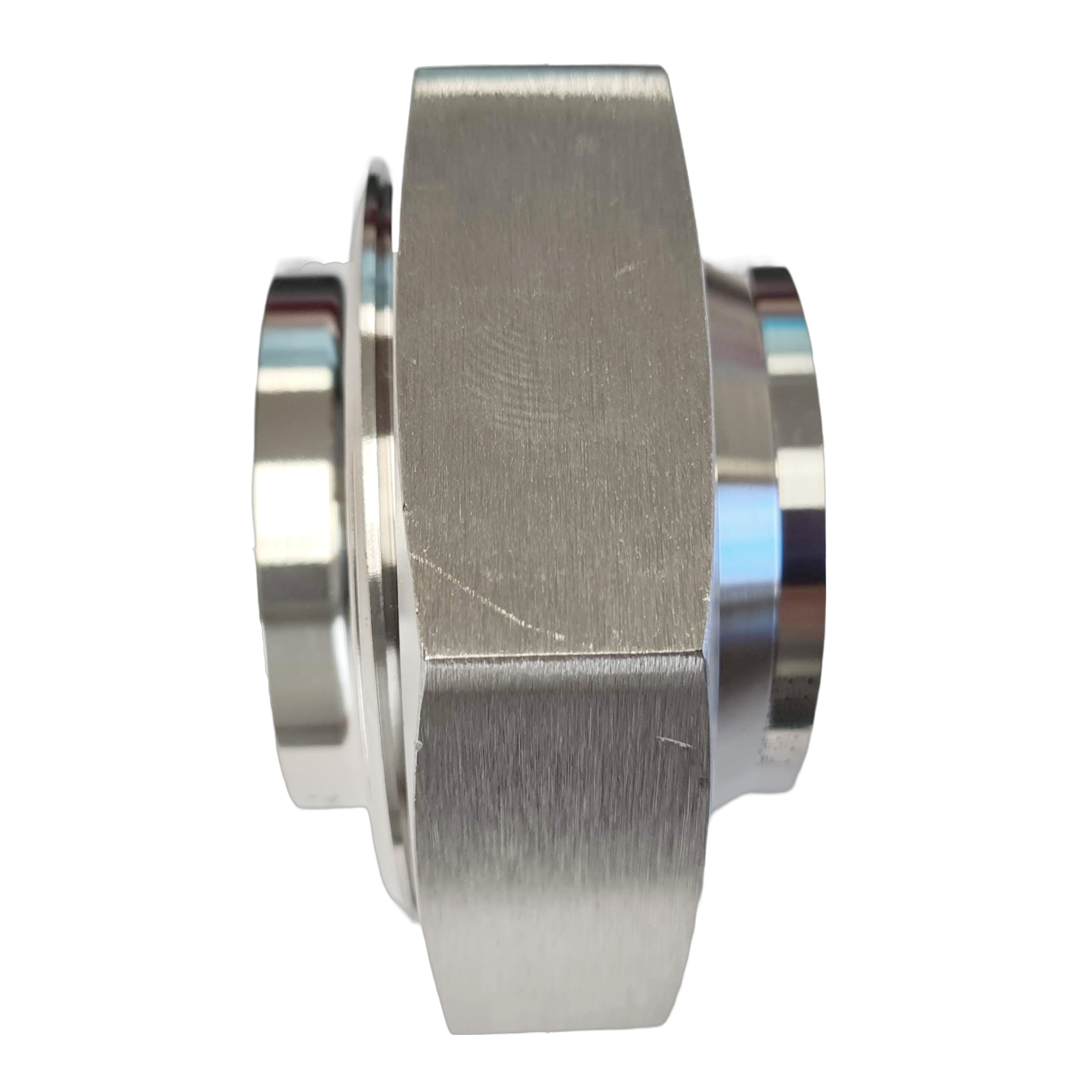

A ball valve uses a spherical closure element with a bored passage to control flow. When the handle or actuator rotates the valve 90 degrees, the internal stainless steel valve ball aligns with the pipeline to allow full flow, or rotates perpendicular to stop it completely. This simple quarter-turn operation provides quick isolation, tight shut-off, and minimal pressure drop compared to many other valve types.

Ball valves are valued for their straightforward design and dependable operation, making them a staple component in modern piping systems.

Benefits of Ball Valves

A stainless ball valve offers several advantages for industrial and hygienic applications. The quarter-turn design allows rapid operation, reducing response time during shutdowns or changeovers. Smooth internal surfaces help minimise product build-up and turbulence, supporting efficient flow and easier cleaning.

Stainless steel ball valves are designed to withstand even the toughest conditions, including high pressure or corrosive environments. They seal tightly to help prevent leaks and reduce the need for ongoing maintenance. Their compact design makes them easy to install and automate, and they can be operated frequently without wearing out or losing performance.

Applications of Stainless Ball Valves

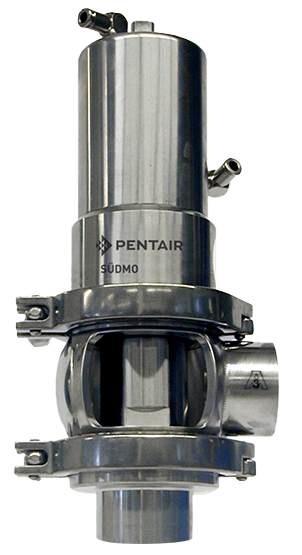

Due to their versatility and durability, ball valves are utilised across a wide range of industries where reliable flow control is crucial. Common industries include food and beverage processing, pharmaceutical and biotechnology, chemical and petrochemical, water and wastewater treatment, mining and minerals processing, energy generation and utilities, and general industrial manufacturing.

When Should You Use a Ball Valve?

Typical applications for stainless steel ball valves include isolating process lines, controlling flow to and from tanks, managing pump suction and discharge points, and regulating utility services such as water, air, and compressed gases. They are also commonly used in compressed air systems and general process isolation points where reliable quarter-turn operation is required.

Choose Stainless Steel Ball Valves from Inox Fittings Australia

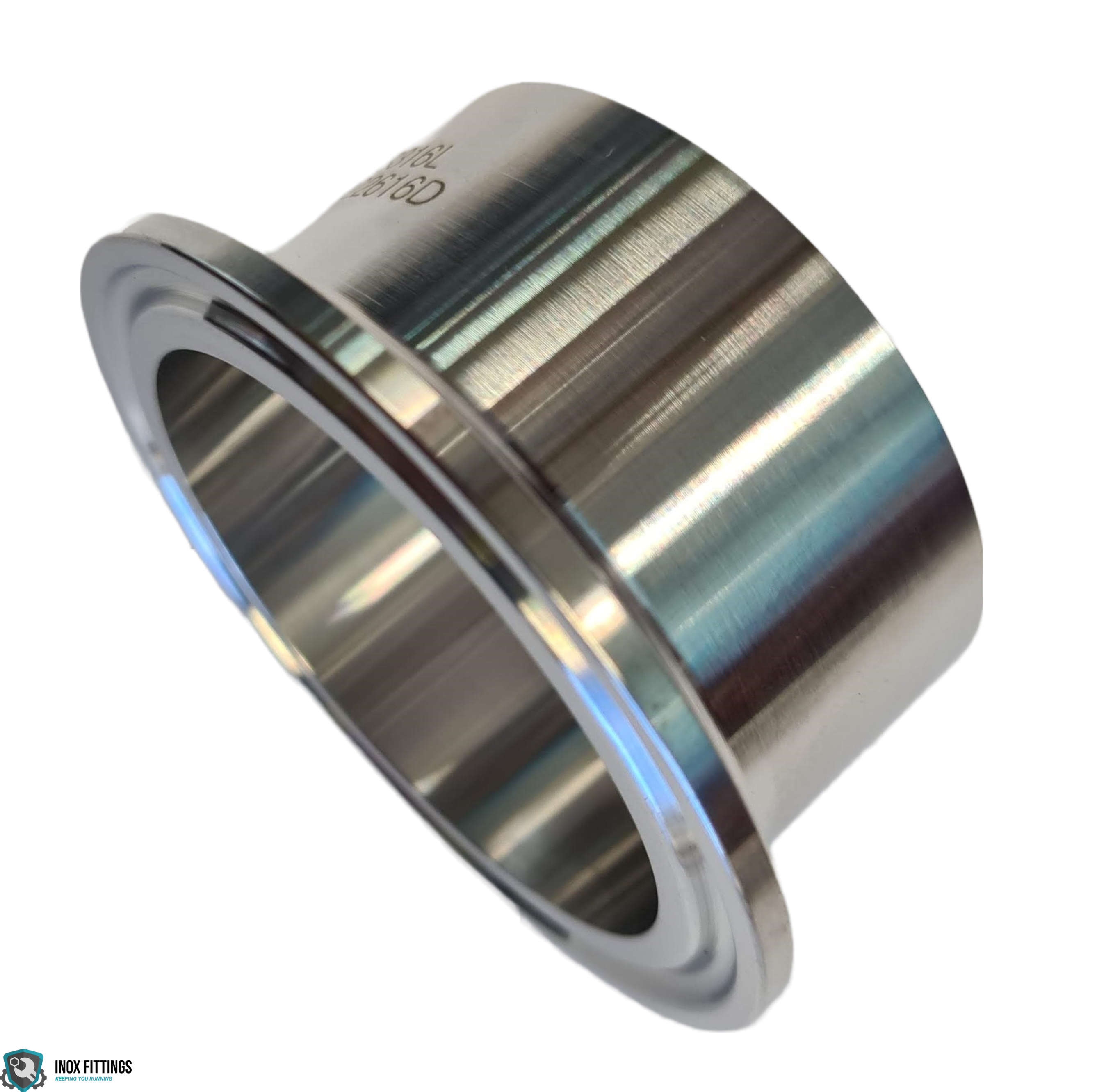

Inox Fittings Australia supplies industrial-grade stainless ball valves engineered for performance, longevity, and compliance across demanding applications. Our team can assist with sizing, pressure ratings, materials, and end connections to ensure the right fit for your system. Explore our full range of stainless steel fittings, including flanges, camlocks, and tri clamps. Contact us today to discuss your requirements or request a quote.

FAQs

What is a ball valve used for?

Ball valves are used for quick isolation and flow control in piping systems. They provide tight shut-off with minimal pressure drop, making them ideal for isolating process lines, controlling tank flow, and managing utility services like water, air, and compressed gases.

Why choose stainless steel ball valves?

Stainless steel ball valves offer superior corrosion resistance, durability, and hygienic properties. They withstand high-pressure and corrosive environments, seal tightly to prevent leaks, and require minimal maintenance, making them ideal for demanding industrial applications.

What industries use ball valves?

Ball valves are used across food and beverage processing, pharmaceutical, chemical, water treatment, mining, energy generation, and general industrial manufacturing. Their versatility and reliable quarter-turn operation make them suitable for diverse flow control applications.