What Are Custom Pipe Fittings?

Custom pipe fittings are specially manufactured components designed to connect pipes in configurations not typically available through off-the-shelf options. They are commonly used when:

- Standard sizes don’t suit the system layout

- The piping must meet unique pressure, temperature, or flow requirements

- Equipment needs retrofitting or replacement parts that aren’t mass-produced

- Aesthetic or functional design constraints require precision shaping

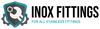

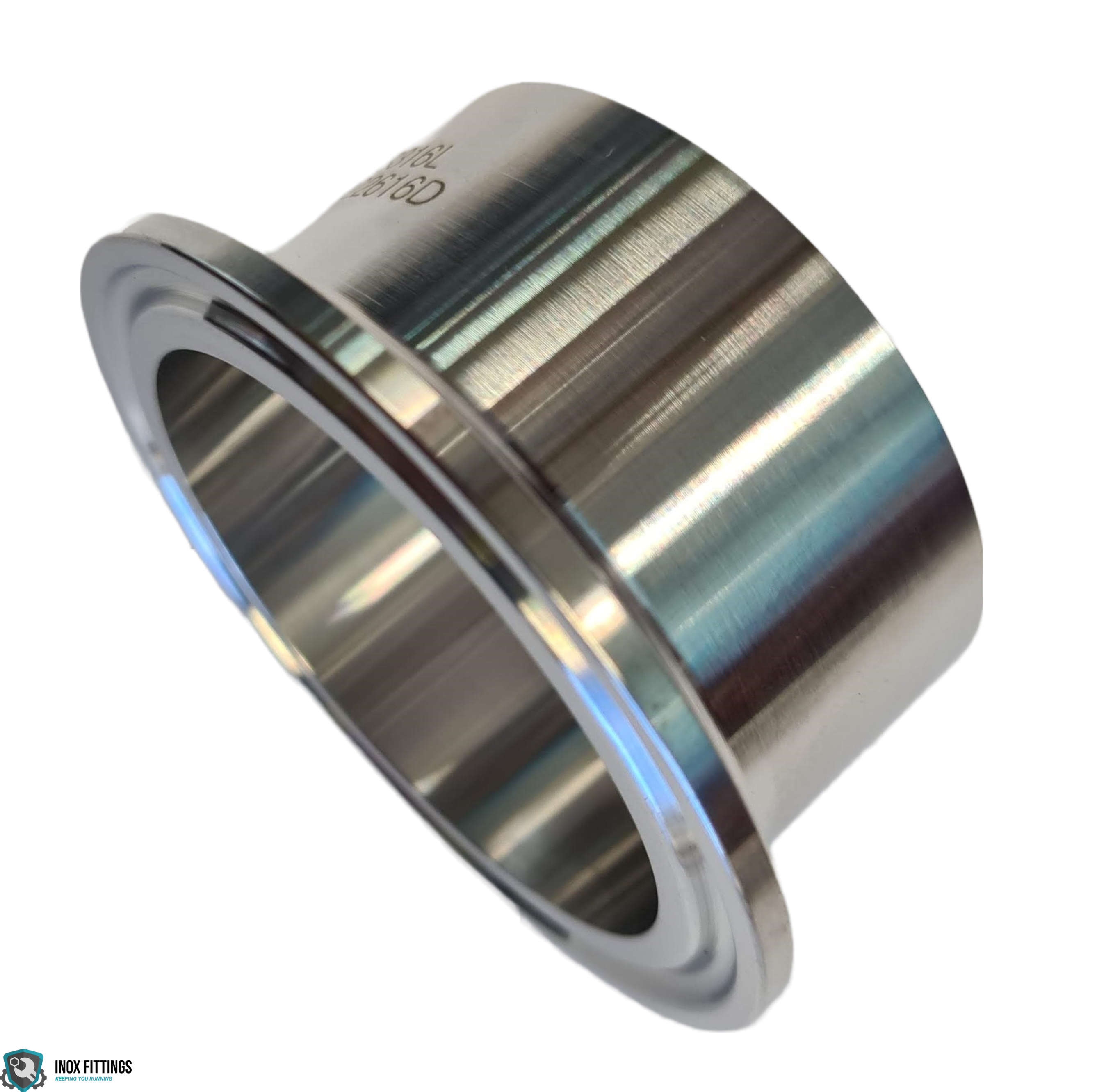

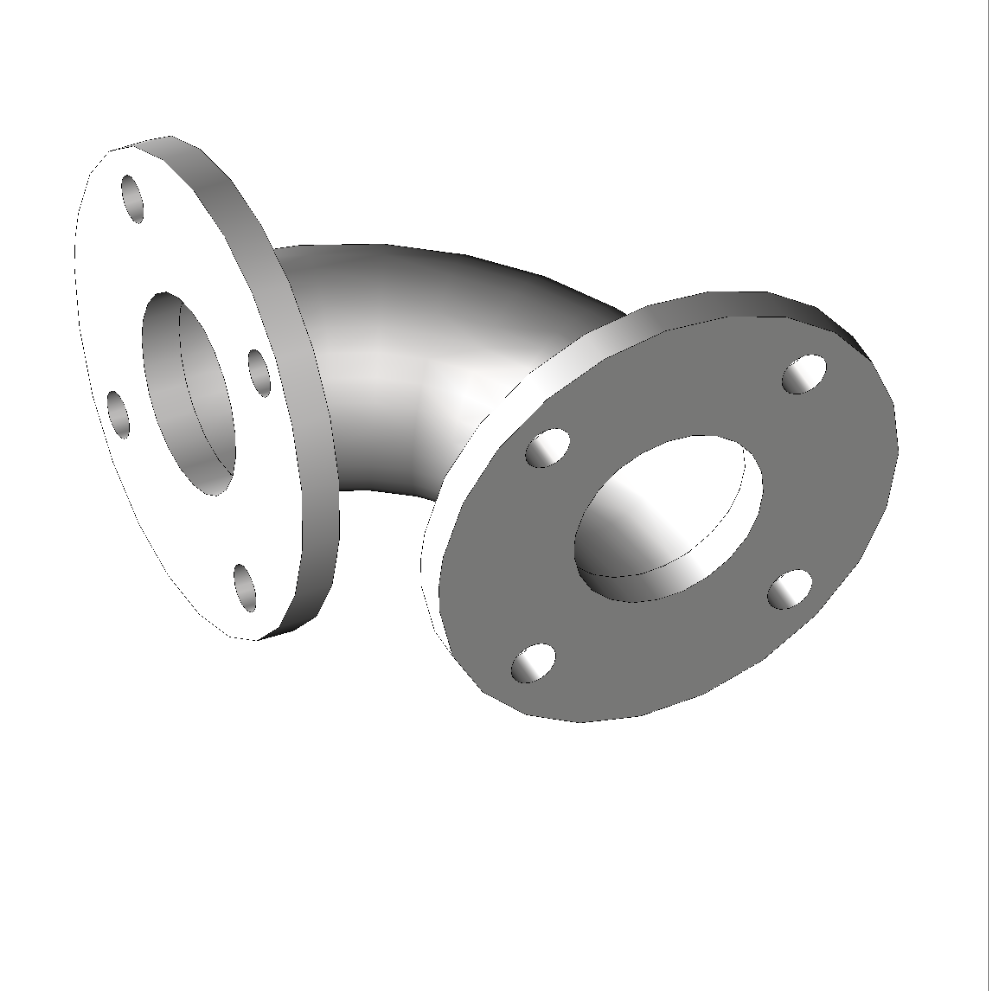

These fittings can include elbows, tees, reducers, connectors, and custom hose fittings, all built to exact project specs and tolerances.

Industries that Rely on Custom Fittings

A wide range of sectors benefit from custom piping components:

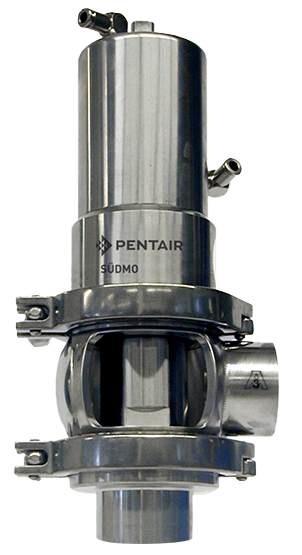

- Food and Beverage: Sanitary-grade custom stainless steel fittings ensure hygiene compliance and optimal flow in tight processing spaces.

- Mining and Resources: Harsh environments require tough materials and tailored sizes to fit into rugged systems.

- Pharmaceuticals: Precision-engineered fittings help maintain sterile conditions and meet regulatory standards.

- Marine and Offshore: Saltwater-resistant alloys and accurate dimensions are critical for long-term reliability.

- Manufacturing: Complex production lines often require bespoke connections that integrate with existing equipment.

Whether you're running a facility in Perth or managing pipeline infrastructure in regional QLD, Australian custom pipes must meet strict local standards. Inox Fittings delivers every time.

Why Choose Custom Stainless Steel?

Stainless steel is the go-to material for durability, hygiene, and corrosion resistance. When it comes to custom fabrication, it offers:

- High strength-to-weight ratio

- Excellent weldability and shaping

- Longevity even in extreme environments

- Easy cleaning and low maintenance

At Inox Fittings, our custom stainless steel components are fabricated to exact standards, using premium 316L and 304 grades depending on your project’s performance requirements.

In-House Expertise and Fabrication

With over 25 years of industry experience, Inox Fittings Australia provides problem-solving. Our team works closely with engineers, contractors, and project managers to design and deliver custom pipe solutions tailored to specific layouts, flow demands, and compliance needs.

We use precision CNC machining and advanced fabrication methods to ensure every component fits the first time. Plus, our local manufacturing capabilities mean faster lead times and tighter quality control across the board.

Fast Turnaround, National Delivery

We understand the cost of project delays. That’s why Inox Fittings offers rapid production and Australia-wide delivery – whether you need a single fitting or a full custom hose fittings package.

We also supply companion parts like flanges, valves, and hygienic fittings to streamline your procurement process.

Custom Isn’t Complicated with Inox

Our customisation process is simple:

- Share your specs or system drawings

- Our team will design a solution or confirm technical requirements

- Receive a fast quote and lead time

- We fabricate and ship directly to your site

We also offer same-day dispatch for urgent orders (subject to availability) and technical advice from local experts who understand Australian compliance and site conditions.

Get Your Perfect Fit – Custom Pipe Fittings Made Easy

Off-the-shelf doesn’t always fit, and that’s where Inox Fittings Australia comes in. From custom stainless steel elbows and reducers to precision custom hose fittings, we’re here to keep your systems running smoothly and efficiently.

Contact us today to discuss your requirements or request a trade account for access to tailored pricing, technical support, and fast turnaround on all your Australian custom pipes.