Types of Compression Pipe Fittings

Choosing the right type of compression pipe fittings is easier when you know what’s available. Here’s a quick overview:

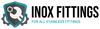

Compression Tube Fittings

These are your go-to fittings for connecting tubing, whether it’s made of metal or plastic. They use a nut, ferrule (or ring), and a fitting body to form a leak-proof connection. Their compact size makes them perfect for tight spaces.

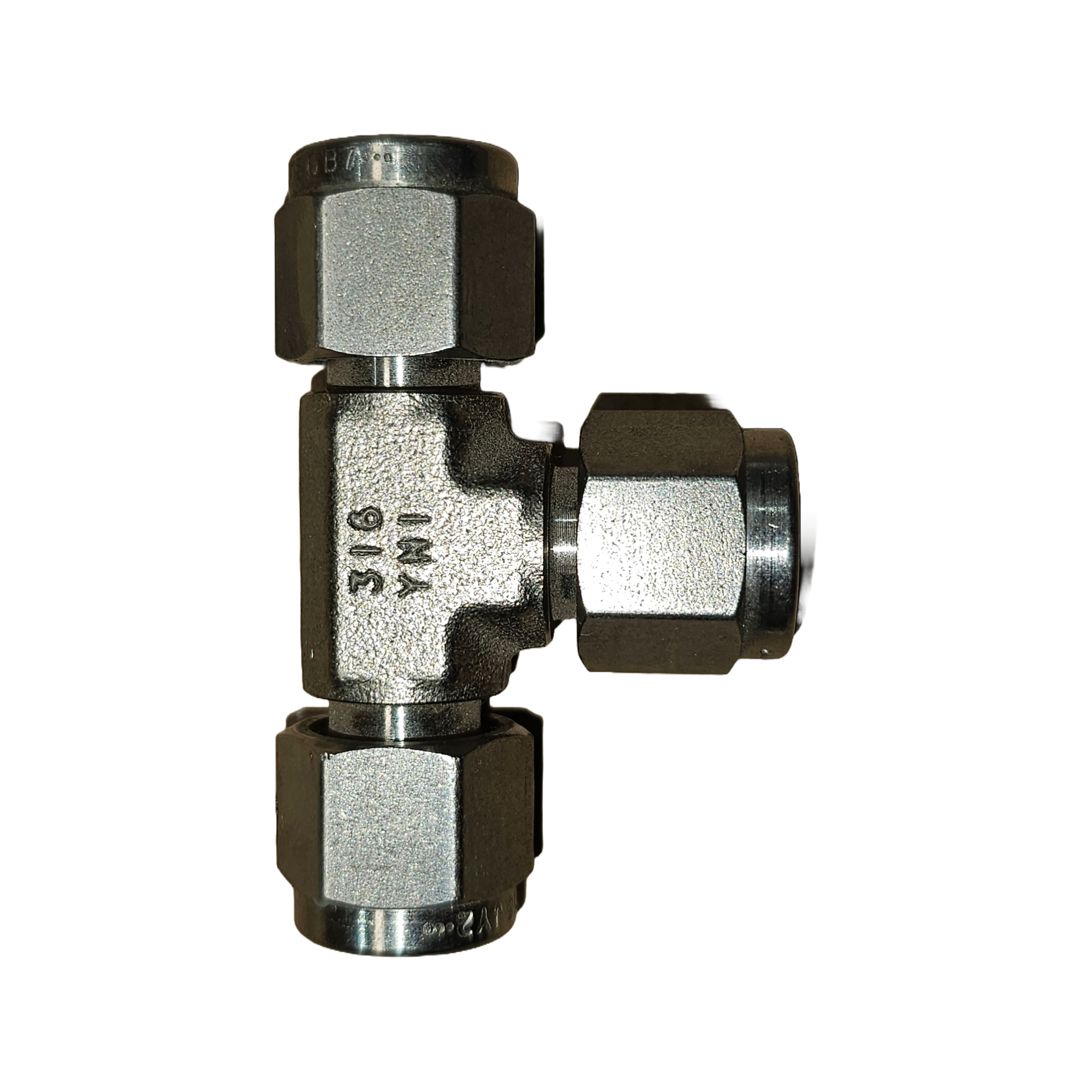

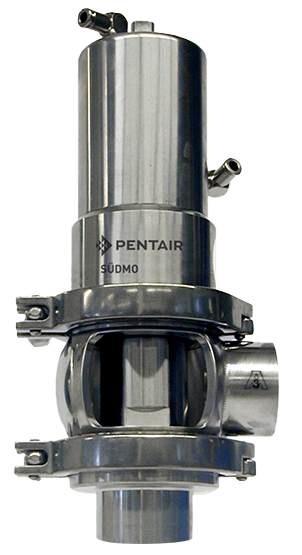

Stainless Steel Compression Fittings

Designed for tough conditions, stainless compression fittings excel in environments where corrosion or wear is a concern. You’ll often see them in industries like food processing or chemical handling, where safety and hygiene are non-negotiable.

Dual-Ferrule Compression Fittings

If you’re working with high-pressure systems or sensitive setups, these fittings are a lifesaver. With two ferrules for extra grip and sealing power, they provide an added layer of reliability that’s hard to match.

How Compression Fittings Work

Compression fittings work by creating a tight seal. When you tighten the nut, the ferrule compresses against the tubing and the fitting body, locking everything in place. This simple mechanism keeps leaks at bay and ensures a solid connection.

Choosing the Right Compression Fittings

Picking the right compression pipe fittings can make or break your project. Here’s what to consider:

Material

If your system is exposed to moisture, chemicals, or extreme conditions, stainless steel compression fittings are the way to go. They’re tough, durable, and resistant to rust.

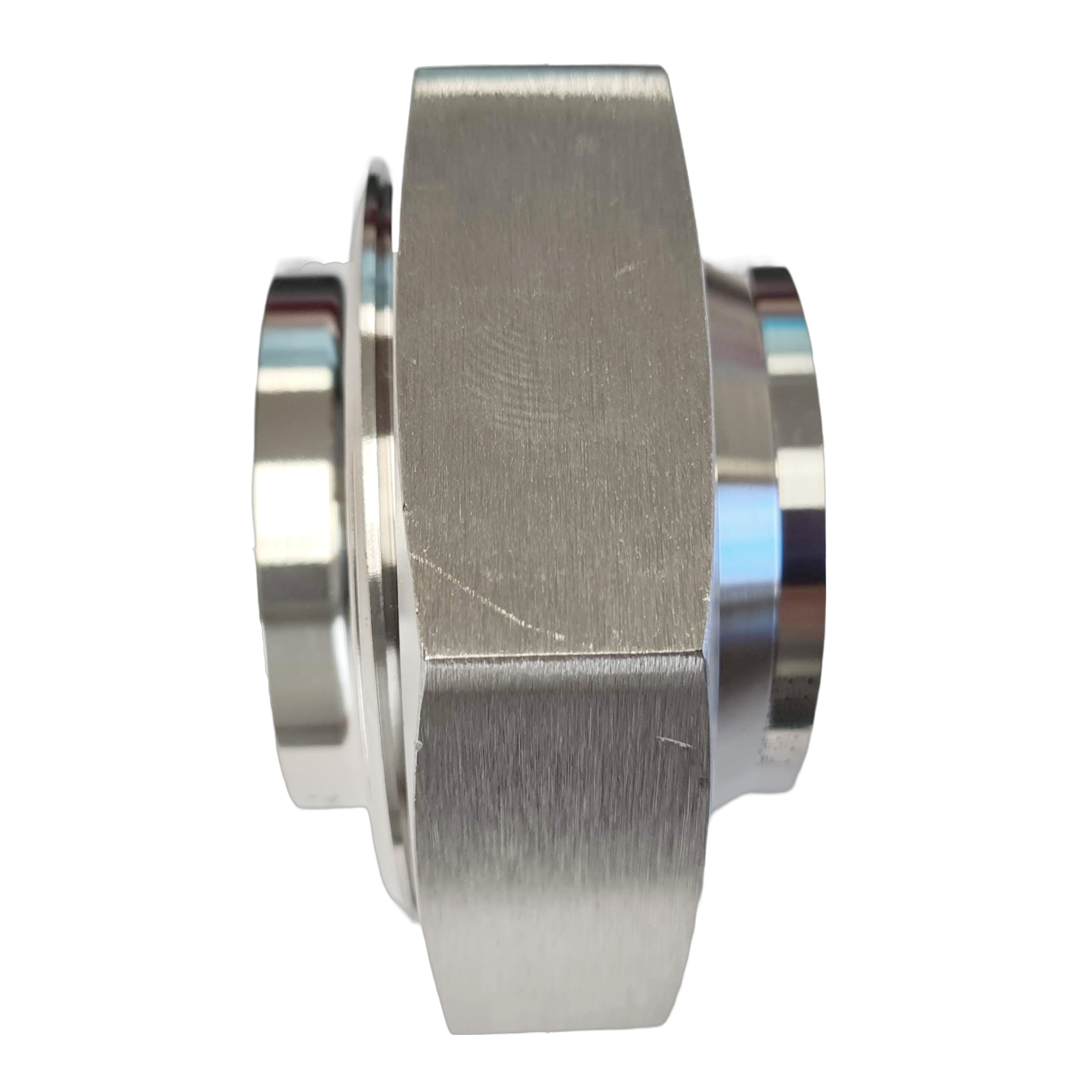

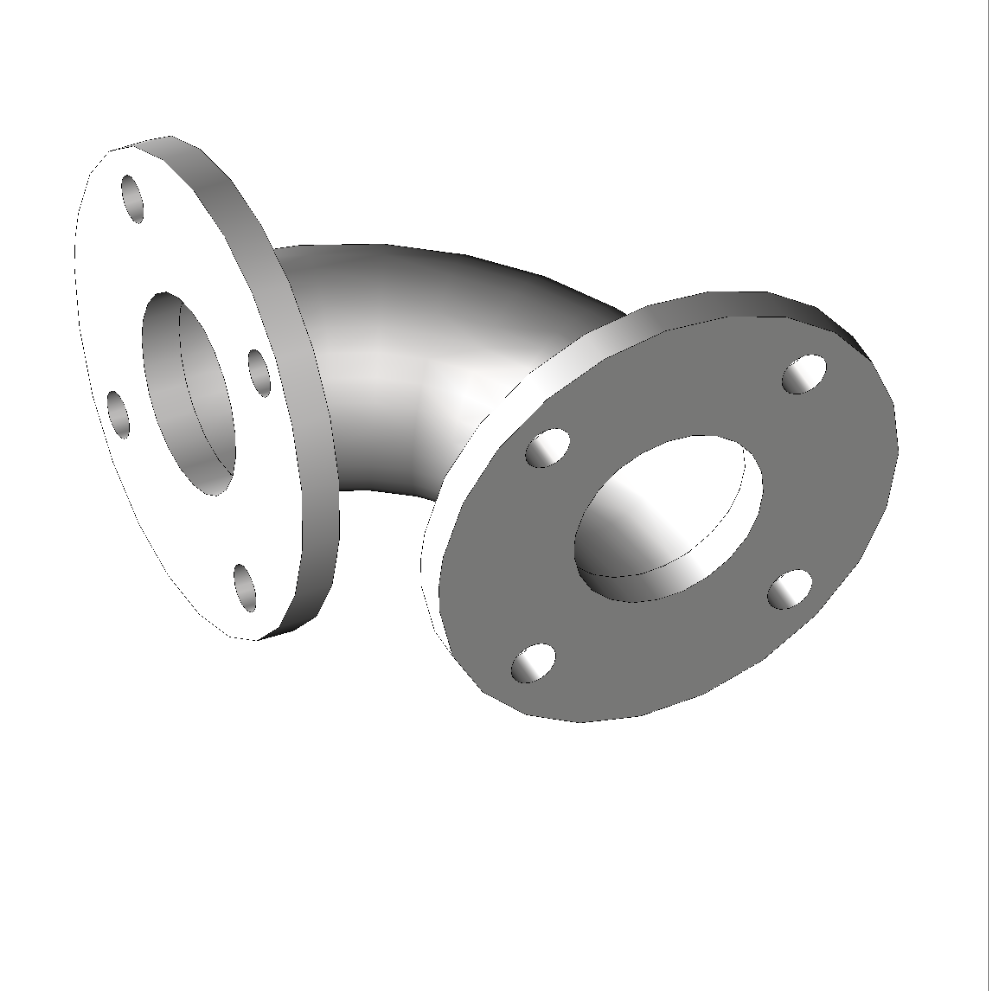

Size and Compatibility

Get the size right to avoid headaches later. Also, make sure your fittings are compatible with other components, like BSP fittings, tri-clover fittings, or stainless tube fittings.

Pressure Requirements

For high-pressure systems, opt for dual-ferrule fittings. For simpler setups, standard compression fittings will do the trick.

Ease of Use

If maintenance or frequent disassembly is a possibility, choose fittings that are easy to install and reassemble without damaging the parts.

Benefits of Compression Tube Fittings

- User-Friendly: Installing these fittings is straightforward—no welding or soldering is needed.

- Versatile: They work with all tubing materials, including plastic, copper, and stainless steel.

- Leak-Free: Designed for a secure seal, they help prevent leaks in fluid and gas systems.

- Durable: With options like stainless steel compression fittings, you get long-lasting performance, even in tough environments.

Shop Compression Fittings at Inox Fittings

Looking for high-quality compression tube fittings? You’re in the right place. Inox Fittings has a wide range of options to suit your needs, whether dealing with high-pressure systems, corrosive environments, or food-grade applications. Our products integrate seamlessly with cam lock plumbing fittings and other essential components for a streamlined setup.

FAQs

What are compression fittings used for?

These fittings connect pipes and tubes in plumbing, gas lines, and industrial systems. They’re instrumental in setups where welding or soldering isn’t practical.

Are compression fittings reusable?

Yes, as long as the components, such as the ferrule and threads, remain intact. Always check for wear before reusing.

What’s the difference between compression fittings and threaded fittings?

Compression fittings rely on a ferrule to create a seal, while threaded fittings use screw-like threads. Compression fittings are often favoured for their ease of installation and leak prevention.